Project Description

The Advantage is a revolution in the development of offset printing blankets for the printing industry. The characteristics of its unique construction, which is based on the cord carcass, brings outstanding advantages up to 30% saving in comparison with standard offset printing blankets in the printing process.

Blanket designed for sheetfed printing jobs where mixed ink systems are in use on the same press.

| COLOR TYPE | Indigo |

| FACE COMPOUND | For UV and oxidation ink drying systems |

| CONSTRUCTION | Cord Carcass |

| TYPE | Compressible |

| SURFACE FINISH | Ground and polished |

| SURFACE ROUGHNESS, RA | 0,60 – 0,90 µm |

| MICRO HARDNESS | 68 +/- 3 IRHD |

| STRETCH | < 0,70 % at 500 N/5 cm |

| NOMINAL THICKNESS | 1,95 mm (ISO 12636) | 1,70 mm (ISO 12636) |

| GAUGE LOSS | ≤ 0,02 mm |

| BOTTOM LAYER | Water/Solvent sealed |

| PACKING & TENSIONING | Conform to OEM instructions |

![]() Heatset

Heatset

![]() Coldset

Coldset

![]() Packaging

Packaging

![]() Coating

Coating

![]() Metal

Metal

![]() Continuous F.

Continuous F.

![]() Recommended

Recommended ![]() Suitable

Suitable ![]() Not Recommended

Not Recommended

![]() Conventional

Conventional

![]() Hybrid

Hybrid

![]() Recommended

Recommended ![]() Suitable

Suitable ![]() Not Recommended

Not Recommended

-

Dimensional Stability

-

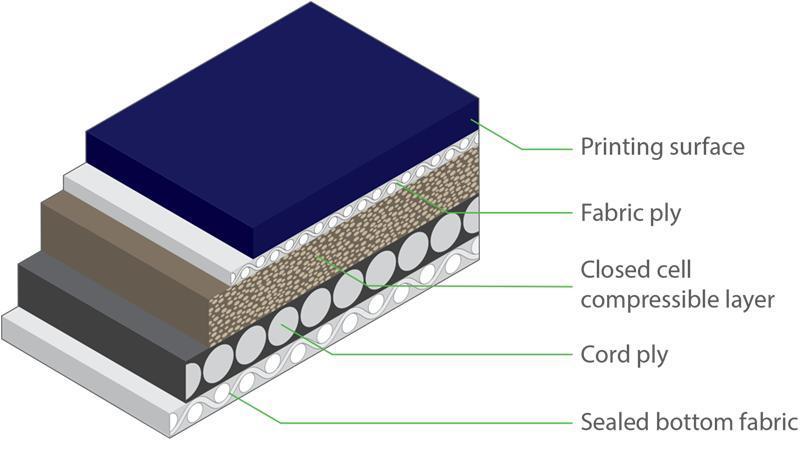

Closed Cell Compressible Layer

-

Microground Printing Surface

-

Sealed Bottom Layer

-

Almost no sinking or stretching giving the blanket exceptional dimensional stability. After mounting no need for further re-tensioning thus leading to reduced down time.

-

New compressible layer coupled with the radial cord carcass improves durability, gives excellent shock absorption and rapid recovery. Resists solvent penetration, reduces the risk of de-lamination.

-

The specially formulated mix mode surface compound enables excellent ink transfer and dot reproduction on a wide range of paper/carton qualities. High resistance to swelling against non-aggressive UV drying inks and cleaning agents. Recommended for use with daylight fluorescent inks and metal-pigmented inks and for alternating operation with conventional, mineral-oil-based and UV inks.

-

Gives added protection against water and chemical penetration.

DOWNLOADS: